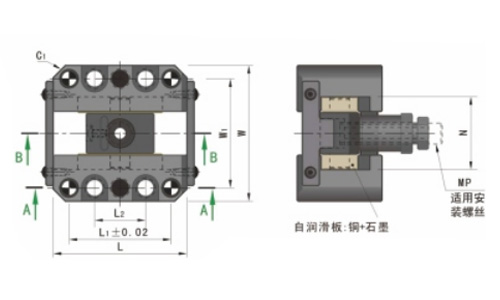

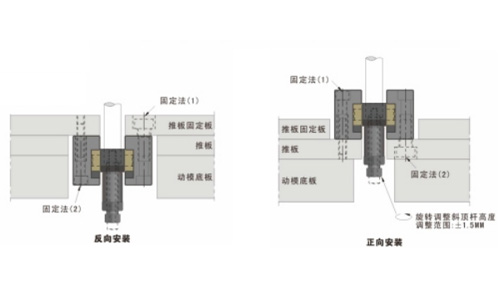

The Inclined Ejector Core Units are designed for applications requiring the internal ejection of molded plastic components, particularly in the context of large molds. These components, installed on the ejector plate, utilize inclined guide rods to smoothly push out the molded plastic parts, completing the ejection process. The primary advantage lies in their ability to efficiently handle the ejection of intricately shaped cores, commonly known as active cores, from the interior surfaces of large molds.

Key Features:

Smooth Operation during Inclined Ejection:

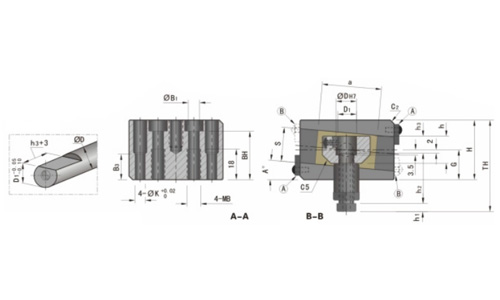

One distinctive feature of the Inclined Ejector Core Units is their ability to facilitate the smooth movement of inclined guide rods during the ejection of cores with intricate shapes. This design ensures a seamless process, reducing the risk of jams or uneven ejections.

Adjustable Fixed Base for Reduced Wear and Tear:

The fixed base of the inclined guide rod is designed to allow movement within a specified range. This innovative feature enables automatic adjustments of the center of gravity, contributing to a reduction in wear and tear on the guide rails and sliding plates. By mitigating friction and abrasion, the Inclined Ejector Core Units extend the operational life of the components, enhancing their durability and reliability.

High Precision without the Hassle of Maintenance:

Precision is a critical requirement in plastic molding processes. The Inclined Ejector Core Units excel in providing high precision during the ejection of active cores. Moreover, the design incorporates features that minimize the need for regular maintenance. This not only ensures consistent performance over time but also reduces downtime and associated costs.

Easy Installation for Enhanced Productivity:

Manufacturers benefit from the straightforward installation process of the Inclined Ejector Core Units, resulting in improved production efficiency. The simplicity of installation not only saves time but also allows for seamless integration into existing molding systems. This user-friendly design enhances overall productivity by reducing setup time and streamlining production workflows.

Applications:

The Inclined Ejector Core Units find widespread application in scenarios where the internal ejection of plastic components, particularly those with intricate shapes, is required. Some notable applications include:

Large Mold Environments:

These units are specifically tailored for use in large molds, where the internal ejection of molded parts poses unique challenges. The Inclined Ejector Core Units excel in efficiently handling the ejection of active cores from expansive molds, ensuring a smooth and reliable process.

Complex Geometries:

Manufacturers dealing with molds that produce plastic components with intricate geometries benefit from the Inclined Ejector Core Units. The smooth operation and precise ejection capabilities make them suitable for molds with complex shapes and designs.

High-Volume Production:

In environments characterized by high-volume production, the Inclined Ejector Core Units shine in terms of their ease of installation and low-maintenance requirements. Their reliable performance contributes to sustained productivity in scenarios where efficiency is crucial.

In conclusion, the Inclined Ejector Core Units offer a pragmatic solution for manufacturers grappling with the challenges of internal ejection in large plastic molding processes. Their key features, including smooth operation, adjustable fixed bases, high precision, and easy installation, make them a reliable choice for a range of applications. By addressing the specific needs of molds dealing with intricate shapes and designs, these units contribute to improved efficiency, extended component life, and enhanced overall productivity in the plastic molding industry.