Email: zhanmeng0168@163.com

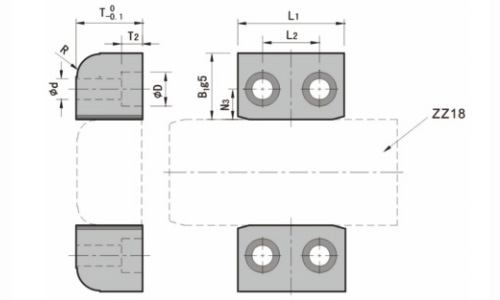

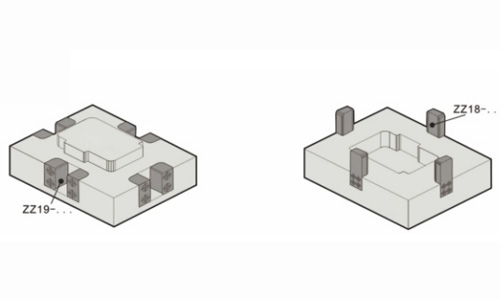

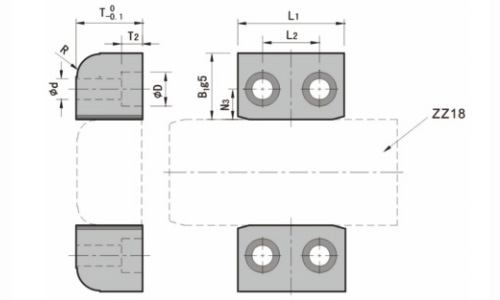

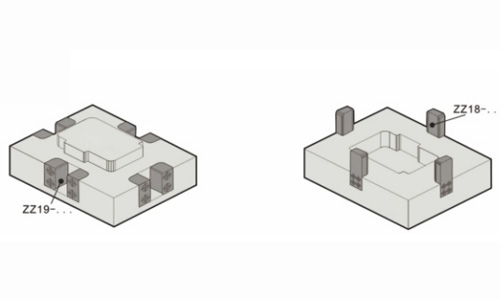

| Code | R | T2 | D | d | N3 | L2 | B1 | T | L1 | @¥/P |

| ZZ19-18-18-27 | 6 | 5.7 | 10 | 5.5 | 8 | 12 | 18 | 18 | 27 | |

| ZZ19-20-22-36 | 6.8 | 11 | 6.6 | 10 | 16 | 20 | 22 | 36 | ||

| ZZ19-25-30-46 | 8 | 9 | 15 | 9 | 11 | 24 | 25 | 30 | 46 | |

| ZZ19-32-32-56 | 10 | 11 | 18 | 11 | 16 | 30 | 32 | 32 | 56 | |

| ZZ19-35-35-56 | 12 | 35 | 35 | |||||||

| ZZ19-40-50-76 | 15 | 13 | 20 | 13.5 | 17 | 40 | 40 | 50 | 76 | |

| ZZ19-45-65-86 | 20 | 50 | 45 | 65 | 86 |

Custom Mold Elements Components Factory In the world of manufacturing, the design and construction of molds are critical to the quality, eff...

READ MORECustom mold elements components Factory Mold components are the unsung heroes of modern manufacturing, serving as the backbone for producing...

READ MORESale industrial mold manufacturing components Factory In the manufacturing industry, the longevity of mold components plays a pivotal role i...

READ MORECustom mold elements accessories Supplier In the realm of manufacturing, the role of mold elements cannot be understated. Mold elements are ...

READ MORECustom mold mould elements accessories Supplier Mold elements are essential components in the design and functionality of molds used in vari...

READ MORECustom Mold Elements Components Factory In the world of manufacturing, the design and construction of molds are critical to the quality, eff...

READ MORECustom mold elements components Factory Mold components are the unsung heroes of modern manufacturing, serving as the backbone for producing...

READ MORESale industrial mold manufacturing components Factory In the manufacturing industry, the longevity of mold components plays a pivotal role i...

READ MORECustom mold elements accessories Supplier In the realm of manufacturing, the role of mold elements cannot be understated. Mold elements are ...

READ MORECustom mold mould elements accessories Supplier Mold elements are essential components in the design and functionality of molds used in vari...

READ MORECustom Mold Elements Components Factory In the world of manufacturing, the design and construction of molds are critical to the quality, eff...

READ MORECustom mold elements components Factory Mold components are the unsung heroes of modern manufacturing, serving as the backbone for producing...

READ MORESale industrial mold manufacturing components Factory In the manufacturing industry, the longevity of mold components plays a pivotal role i...

READ MOREZhanmeng Mould Parts Co, Ltd. is a professional manufacturer specializing in the production, sales, and design of precision mold parts.

Contact Information

Cell phone: +86-13018824444 /

+86-18658685895

Cell phone: +86-13968153627

Landline: +86-576-84335476

Fax: +86-576-84330857

Email: zhanmeng0168@163.com

Add: 23 Qingfeng Avenue, Beicheng Development Zone, Huangyan District, Taizhou, Zhejiang, China.

Mobile Site