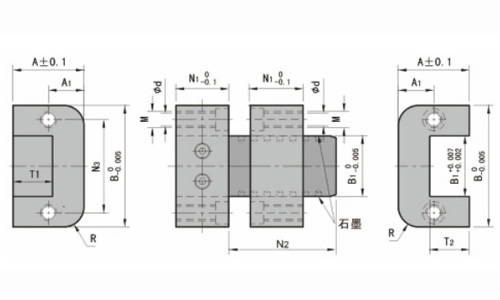

Precision Locating Metal Square Interlocks are meticulously engineered components designed to fulfill a role in the manufacturing process, specifically in the domain of mold alignment. These interlocks play a role in ensuring the precise final centering of the mold within the parting line, contributing to the overall accuracy and efficiency of the machining process.

One of the key advantages of Precision Locating Metal Square Interlocks lies in their ease of integration into the manufacturing workflow. Designed to streamline processes, these interlocks enable easy fitting through vertical machining, requiring only a single clamping operation. This simplicity not only enhances operational efficiency but also contributes to a more seamless and straightforward production process.

The versatility of Precision Locating Metal Square Interlocks is reflected in the availability of multiple standard sizes. This variety allows manufacturers to choose the interlock size that suits their specific requirements, adding a layer of adaptability to these components. The range of standard sizes caters to diverse applications, providing manufacturers with the flexibility needed to address the unique demands of various projects.

An integral function of Precision Locating Metal Square Interlocks is their role in preventing mold misalignment. In manufacturing environments where molds are frequently utilized, ensuring precise alignment is imperative to the success of the overall process. These interlocks serve as a reliable solution to this challenge, acting as a safeguard against misalignments that could compromise the integrity of the final product.

Additionally, the protective aspect of Precision Locating Metal Square Interlocks extends beyond mold alignment. These interlocks also play a crucial role in shielding small inserts or components within the mold. This protective function is especially valuable in applications where delicate or intricate elements are integrated into the manufacturing process. By reducing the risk of damage to these smaller components, Precision Locating Metal Square Interlocks contribute to the overall durability and reliability of the final product.

The effectiveness of Precision Locating Metal Square Interlocks is further underscored by their compatibility with vertical machining operations. This compatibility enhances their applicability across a wide range of machining processes, making them a versatile choice for manufacturers operating in diverse industries. The ability to seamlessly integrate these interlocks into existing machining setups adds to their appeal, offering a hassle-free solution for enhancing precision in mold alignment.

In addition to their functional attributes, Precision Locating Metal Square Interlocks adhere to stringent quality standards. Rigorous testing and quality control measures are implemented during the manufacturing process to ensure that each interlock meets the specified performance criteria. This commitment to quality not only instills confidence in manufacturers but also underscores the dedication of the interlocks' manufacturers to delivering reliable and consistent products.

In conclusion, Precision Locating Metal Square Interlocks stand as a testament to precision engineering and thoughtful design in the realm of manufacturing components. Their role in ensuring the accurate alignment of molds and protecting small inserts underscores their significance in contributing to the quality and reliability of the final products. With a focus on simplicity, adaptability, and effectiveness, these interlocks prove to be valuable assets in the pursuit of precision in manufacturing processes.